Table Of Content

The qualified person must do adequate preplanning to assure the safe erection and use of the scaffold. Preplanning must include determining the necessary type of scaffolding for the job, the maximum load for the scaffold, assuring a good foundation, and avoiding electrical hazards. The common hazards that erectors and dismantlers face include access, collapse, electrical, fall, instability, and struck-by hazards. Scaffold erectors are those employees who have been designated (based on training and experience) by the department to be the employees who are responsible for the erection and maintenance of department scaffolds on the Princeton University campus. Erectors can solicit materials and components from other employees who may be on the ground, but the ultimate adding / subtracting of components to a scaffold shall be accomplished by an authorized scaffold erector.

Scaffold Safety – Planning, Design, Erection and Use

Any discrepancies or differences created in the translation are not binding and have no legal effect for compliance or enforcement purposes. If any questions arise related to the information contained in the translated website, please refer to the English version. Upon successful completion, attendees will receive a certificate, and the client/employer will receive copies of the certificates, the training roster, quizzes, and course evaluations for their records.

Scaffolding Rental vs. Purchase

The front edge of all platforms shall not be more than 14 inches from the face of the work, unless guardrail systems are erected along the front edge and/or personal fall arrest systems are used. Each end of a platform, unless cleated or otherwise restrained by hooks or equivalent means, shall extend over the centerline of its support at least 6 inches. Prior to assembly, a qualified person must design the scaffold and set the specifications for using it.

§1637. General Requirements.

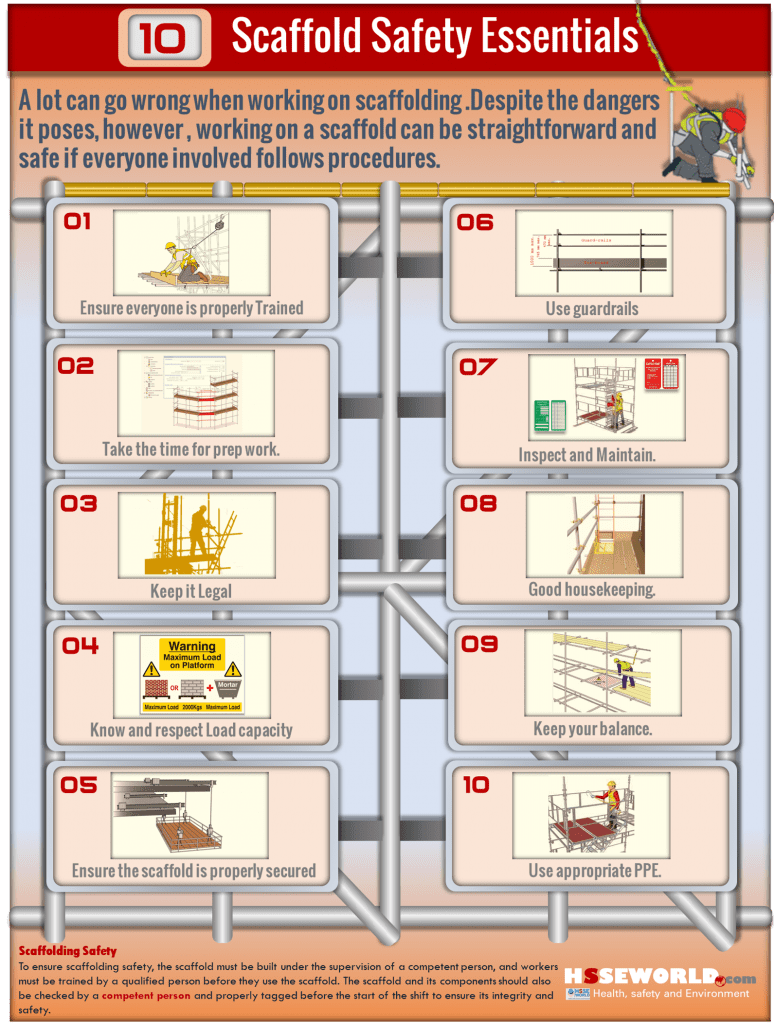

Scaffolds must not be erected, used, dismantled, altered, or moved such that they or any conductive material handled on them might come closer to exposed and energized powerlines. OSHA provides minimum distance guidelines for insulated and uninsulated lines depending on the voltage. When it comes to using scaffolding, employers must ensure that scaffolds and scaffold components are not loaded in excess of their maximum intended loads or rated capacities, whichever is less.

Companies cited with serious violations for deadly scaffolding collapse in Charlotte - Charlotte Observer

Companies cited with serious violations for deadly scaffolding collapse in Charlotte.

Posted: Thu, 29 Jun 2023 07:00:00 GMT [source]

Staying up-to-date on scaffold safety regulations and industry standards is vital to maintaining compliance, avoiding fines, and fostering a safe work environment. Lindemer also advises that passive fall protection, such as a guardrail, is preferable when working on scaffolding so that users will not have to think about their work positioning or where they are tied off, as they would with a personal fall arrest system. “Every scaffold should be designed by a qualified person who can perform the analysis needed to ensure that it’s designed properly,” says Dale Lindemer, chair of the A10.8 committee.

Load requirements

But the third option—drones—presents a way for inspectors to collect the data they need remotely, without having to put themselves in danger. However, there are some scenarios where buying your own could make sense—here are some things to keep in mind when trying to decide whether to rent or buy scaffolding. There are many factors to consider when trying to decide whether to rent scaffolding or purchase scaffolding. In general, most big companies that use scaffolding choose to rent instead of deal with the logistics and cost that come with buying and storing their own.

In 2020, the Bureau of Labor Statistics Census of Fatal Occupational Injuries (CFOI) reported 52 scaffolding fatalities. By adhering to safety rules, regulations, and best practices, these fatalities could have been avoided. Cal/OSHA standards require scaffolding at heights where ladders are unsafe and there is no permanent structure at least 20 inches wide. Designing scaffolds is not the same as simply building a scaffold to comply with the OSHA regulations since the OSHA regulations are minimum requirements, not instructions or directions for design. A qualified person will incorporate the requirements specified in the regulations in the design, not use the regulations as the design.

Competent Person

Scaffolds are erected, moved, dismantled, or altered only under the supervision and direction of a competent person qualified in scaffold erection, moving, dismantling, or alteration. Such activities are performed only by experienced and trained erectors selected for such work by a competent person. A competent person selects the appropriate scaffold for the task, supervises the assembly of the scaffold system and inspects each component. He must also understand, recognize, control and eliminate any hazards, such as access issues, possible instability and collapse during assembly/disassembly, electrical hazards, and fall and struck-by hazards.

New Guidance on Public Health Emergency Approved Respirators

Scaffolding can be built up from the ground, suspended from the top of buildings, and cantilevered off the sides of structures. Aerial lifts are commonly used for construction projects that require workers to access a variety of different levels in a single day or work cycle. The direct connections to roofs and floors, and counterweights used to balance adjustable suspension scaffolds, must be capable of resisting at least four times the tipping moment imposed by the scaffold operating at the rated load of the hoist. Alternatively, they must withstand a minimum of 1.5 times the tipping moment imposed by the scaffold operating at the stall load of the hoist, whichever is greater.

Many industries deploy scaffolding to get work done, specifically in construction, where millions of employees use scaffolding on a regular basis. One who is capable of identifying existing and predictable hazards in the surroundings or work conditions that are unsanitary, hazardous, or dangerous to employees and who has the authorization to take prompt corrective measures to eliminate them. Educate your employees on how to spot defective flooring planks and any other flaws in the scaffolding system. The business of scaffolding is quite fascinating in that parts and pieces can be assembled in countless combinations to provide elevated worker access.

“Although guardrails are probably the most common form of fall protection, on certain scaffolds, for example single- and two-point suspended scaffolds, you need both a guardrail and a personal fall arrest system,” he says. Cross braces on tubular welded frame scaffolds shall not be used as a means of access or egress. Hook-on and attachable ladders shall be positioned so that their bottom rung is not more than 24 inches above the scaffold supporting level. When hook-on and attachable ladders are used on a supported scaffold more than 35 feet high, they shall have rest platforms at 35 foot maximum vertical intervals.

Cantilever scaffolding (also called needle scaffolding) is made to come out from a building at an angle using a separate scaffold. Images of scaffolding have been found on ancient artifacts such as the Berlin Foundry Cup, a Greek drinking cup made in the 5th century BC. The use of scaffolding dates as far back as the stone age—in fact, there’s evidence that scaffolding was used over 17,000 years ago by those who made the famous paleolithic cave paintings at Lascaux. Wood platforms shall not be covered with opaque finishes, except that platform edges may be covered or marked for identification. Platforms may be coated periodically with wood preservatives, fire-retardant finishes, and slip-resistant finishes; however, the coating may not obscure the top or bottom wood.

After inspectors find these areas, maintenance workers will address those defects by standing on scaffolding to perform their work. Workers commonly can stand on scaffolding to clean windows and other parts of skyrise buildings. Scaffold dismantling and storage are the final steps that can ensure scaffold planks and components are preserved for future use and prevent accidents during disassembly. Since the original approval of the A10.8 standard in 1969, scaffolding work has evolved considerably as materials, components and technology have changed, allowing for a wider variety of scaffolding options for use on work sites.

No comments:

Post a Comment